Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

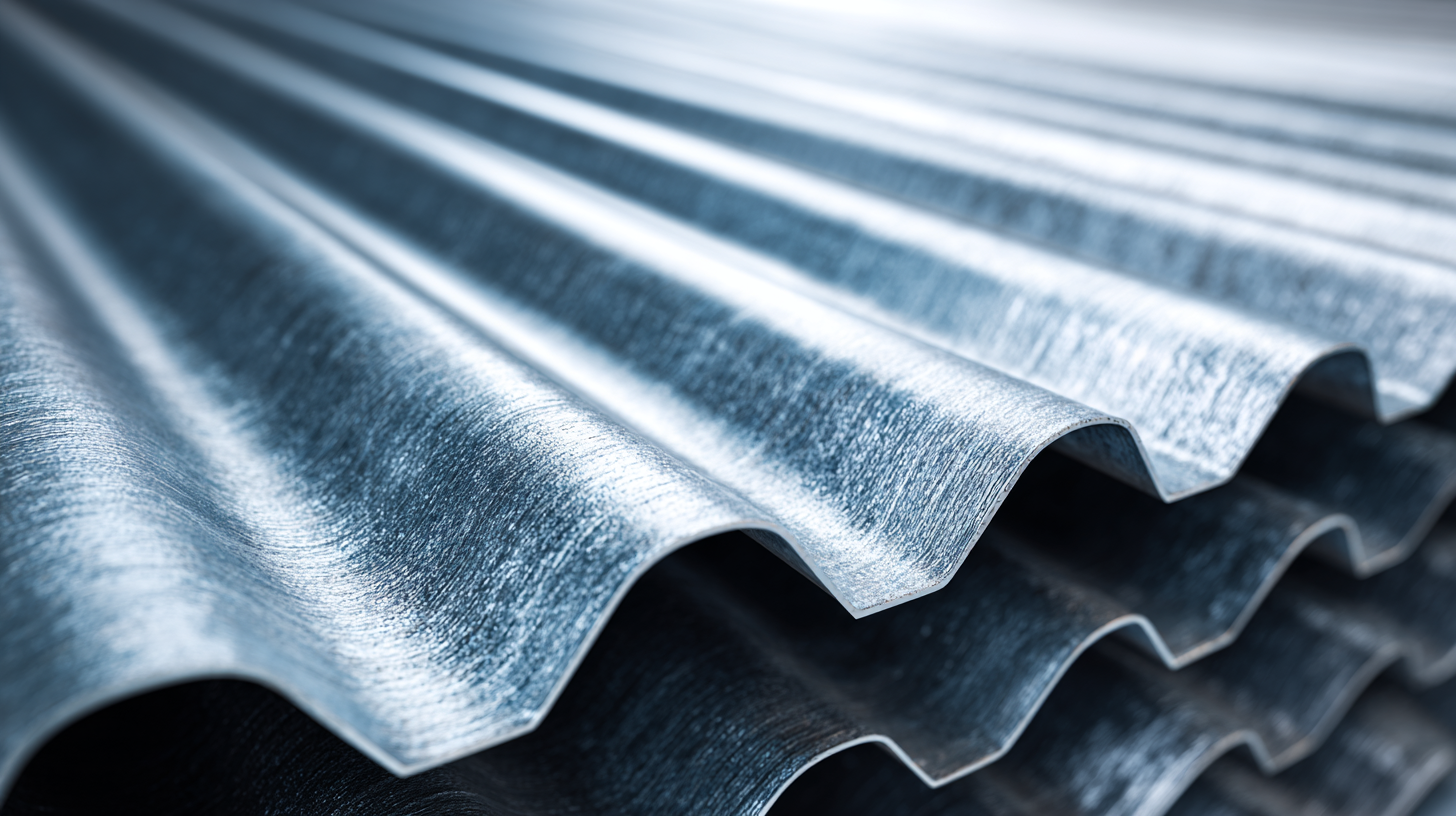

In the rapidly evolving landscape of modern construction, the choice of materials plays a crucial role in determining the durability and efficiency of structures. Among the various materials available, the "Galvanized Corrugated Steel Sheet" emerges as a top contender, combining strength with versatility. According to a report by the Global Steel Secretariat, the global demand for galvanized steel products is projected to reach over 400 million metric tons by 2025, driven by its effectiveness in preventing corrosion and extending the lifespan of building elements. Additionally, the World Steel Association highlights that galvanized steel offers up to 75 years of maintenance-free service life, making it an economically viable solution for construction projects. This blog will explore the unique properties of galvanized corrugated steel sheets and their distinct advantages, illustrating why they have become a favored choice among architects and builders in contemporary construction practices.

Galvanized corrugated steel sheets are a versatile construction material, renowned for their durability and strength. These sheets are made by coating iron or steel with a layer of zinc, which not only provides corrosion resistance but also enhances the material's longevity. The corrugated design adds structural integrity, making it ideal for roofing, siding, and various architectural applications.

Galvanized corrugated steel sheets are a versatile construction material, renowned for their durability and strength. These sheets are made by coating iron or steel with a layer of zinc, which not only provides corrosion resistance but also enhances the material's longevity. The corrugated design adds structural integrity, making it ideal for roofing, siding, and various architectural applications.

When selecting galvanized corrugated steel sheets for modern construction, consider their composition and quality. High-grade zinc coatings can significantly increase the lifespan of the sheets, ensuring they withstand the elements over time. It's also important to check the standards for import and export if you're sourcing these materials internationally. Familiarize yourself with classifications under chapter 72 to ensure compliance and optimal selection for your projects.

Tips: Always verify the zinc coating thickness when purchasing galvanized sheets; a thicker coating usually means better corrosion resistance. Additionally, assess the environmental impact of the materials you choose, as sustainable practices are becoming increasingly essential in modern construction. Lastly, keep abreast of changing regulations regarding steel imports and exports to avoid any compliance issues that could affect your project's timeline.

Galvanized corrugated steel sheets have emerged as a popular choice in modern construction due to their unique combination of durability and versatility. One of the primary benefits is their resistance to corrosion, thanks to the zinc coating that protects the steel from moisture and other environmental elements. This characteristic significantly extends the lifespan of the materials, making them an ideal option for roofs, walls, and various structural components that must endure harsh weather conditions.

In addition to their durability, galvanized corrugated steel sheets are lightweight and easy to install, which can reduce labor costs and construction time. The corrugated design adds structural strength while also allowing for efficient water runoff, minimizing the risk of leaks and damage. Moreover, these sheets are often more cost-effective compared to traditional building materials, providing an economical solution without compromising quality. With their ability to blend functionality and affordability, galvanized corrugated steel sheets are revolutionizing modern architectural designs, offering both aesthetic appeal and practical advantages.

In modern construction, the choice of materials plays a crucial role in sustainability and durability. Galvanized corrugated steel sheets stand out in comparison to traditional materials like wood and concrete. According to a report from the International Organization for Standardization (ISO), galvanized steel has a lifespan of over 50 years when properly maintained, far exceeding that of untreated wood, which typically lasts only 10-15 years. Furthermore, galvanized steel resists corrosion, making it an ideal choice for various climates, thus reducing maintenance costs over time.

When assessing the environmental impact, a 2021 study by the World Green Building Council found that using galvanized steel can lower carbon emissions by up to 40% in comparison with concrete production. This is largely due to steel's recyclability; approximately 90% of steel can be recycled, minimizing waste. In contrast, concrete production is responsible for about 8% of global CO2 emissions, contributing significantly to climate change. As the construction industry continues to evolve, the advantages of galvanized corrugated steel sheets in both performance and sustainability make them a superior choice over traditional building materials.

Galvanized corrugated steel sheets have become increasingly popular in contemporary architecture due to their unique blend of durability and aesthetic appeal. These sheets are often used for roofing and siding in both residential and commercial buildings, providing a robust solution that withstands harsh weather conditions while remaining lightweight. Their corrugated design not only enhances the structural integrity but also adds an industrial charm, making them a favored choice among architects seeking to create modern yet functional designs.

In addition to their structural applications, galvanized corrugated steel sheets are also utilized in innovative ways, such as in cladding for facades, garden structures, or even as decorative elements in interior design. Their versatility allows for various finishes and colors, enabling them to complement different architectural styles. By incorporating these steel sheets, designers can achieve a unique blend of sustainability and modern aesthetics, meeting both functional needs and visual impact in contemporary architecture.

| Dimension | Value |

|---|---|

| Thickness | 0.4 - 1.5 mm |

| Width | 600 - 1200 mm |

| Length | 1000 - 6000 mm |

| Coating Weight | Z120 - Z600 g/m² |

| Corrosion Resistance | High |

| Fire Resistance | Yes |

| Weight | 7 - 25 kg/m² |

| Applications | Roofs, Walls, Fencing, Sheds |

Galvanized corrugated steel sheets have emerged as a popular choice in modern construction due to their exceptional sustainability and durability. The galvanization process, which involves coating the steel with zinc, not only enhances the metal’s resistance to rust and corrosion but also extends its lifespan significantly. This makes it an ideal material for various building projects, from residential homes to commercial structures. The longevity of galvanized steel reduces the need for frequent replacements or repairs, ultimately leading to lower material consumption and waste.

Moreover, the eco-friendly characteristics of galvanized corrugated steel contribute to its appeal in sustainable construction practices. The material is 100% recyclable, meaning that at the end of its life cycle, it can be repurposed without any loss in quality. This reflects a commitment to reducing environmental impact, as recycling steel consumes less energy compared to producing new materials. Additionally, the reflective surface of galvanized sheets can contribute to energy efficiency in buildings by reducing heat absorption, leading to lower cooling costs. Overall, the combination of durability and sustainability makes galvanized corrugated steel an advantageous choice for modern builders looking to meet both functional and environmental standards.